The principle of this machine is putting the disorder nails in the vibrating disk. Then the vibrating disk will put the nails in order and through the feeding mouth to the welding part, then it will automatically oiled rust, drying, counting and coiling in a roll. This coil nail making machine is a special kind of automatic welding equipment. The nails will be welded by two copper coated wires at a certain angle, 15° to 16°, then the welded nails are coiled to a fixed length as per the counter to cut off, forming a coil shape with flat top or cone top.all size of coil nails and coil roofing nails are widely used for pallet,roofing,construction,etc

Coil Nail Machine Description:

Machine Features

1. The coiled nails are automatically formed and binded with rubber bands, and the finished products are automatically produced and pushed to the finished product platform

The traditional operation of manual rubber banding is removed. To improve the previous models, the finished coiled nails must be manually caught in time, otherwise the coil nails will be broken and deformed , Which greatly reduces the work intensity of workers and the requirements for workers’ skills and proficiency, so that improves production efficiency

2.Improved finished product platform

the platform can store about 60 finished coil nails, and the direction of the finished product can be adjusted

3.New improved welding base

No need to adjust the height of the welding base with different sizes of welding wheels (for example: do 19-37 welding position nails, the height of the welding base does not need to be adjusted), reducing welding waste and technical requirements.

4. New patented coil nail cutting technology

the probability of continuous cutting after simple debugging is less than 1/10 of the ordinary typical,reducing the waste rate.

5. Improve automatic operation

Added protection for welding wire used up or burnt, protection for coiled nails that are not cut off, and protection for rubber bands are used up on automatic rubber binding mechanism . And display its position on the touch screen

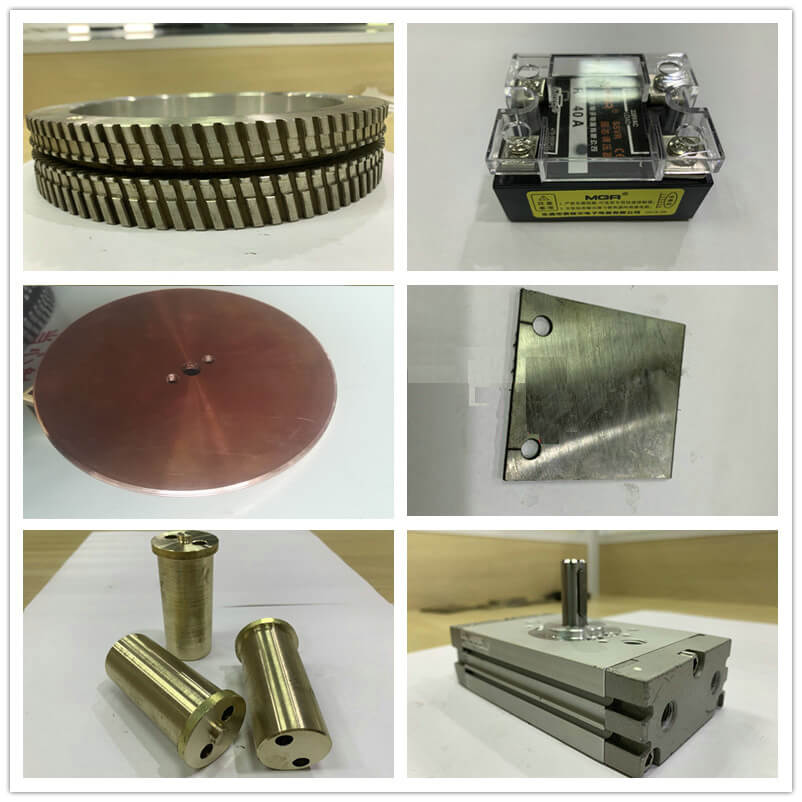

Spare Parts

Package & Loading