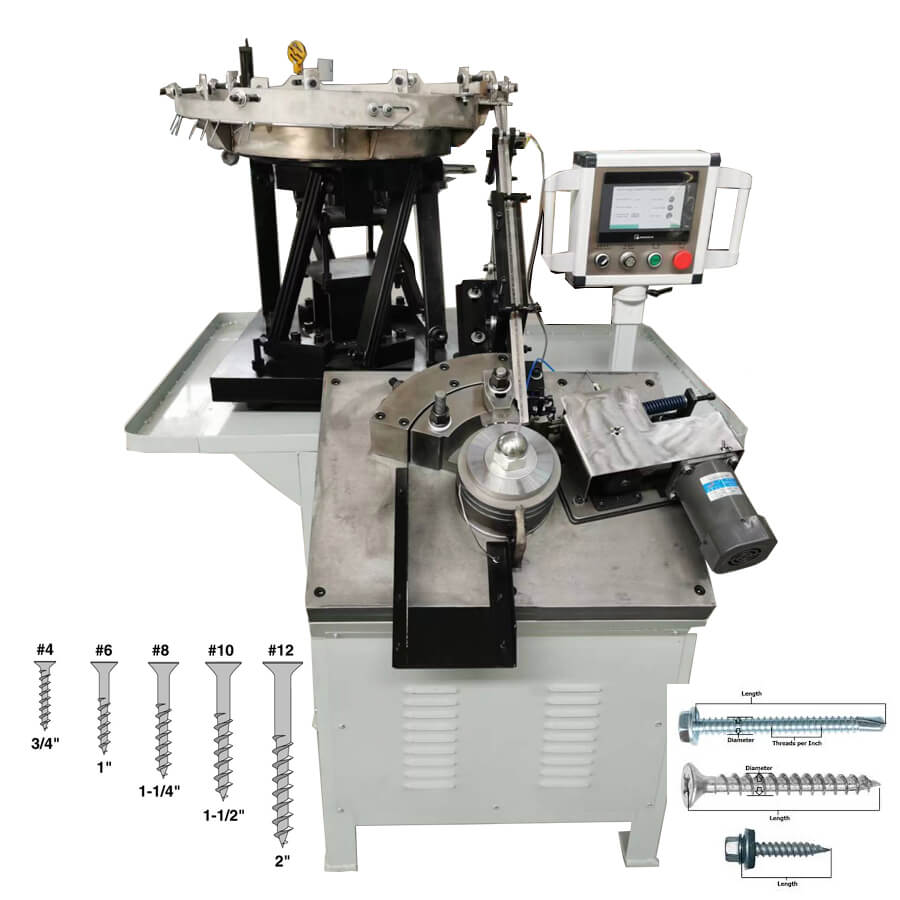

nail thread rolling machine is specially supplied for cold heading bearing steel, carbon steel, stainless steel, copper, aluminum etc metal ball billet. Whole working process, such as feeding, cutting, cold heading and ejection processes are automatically and continuously.

Machine Description:

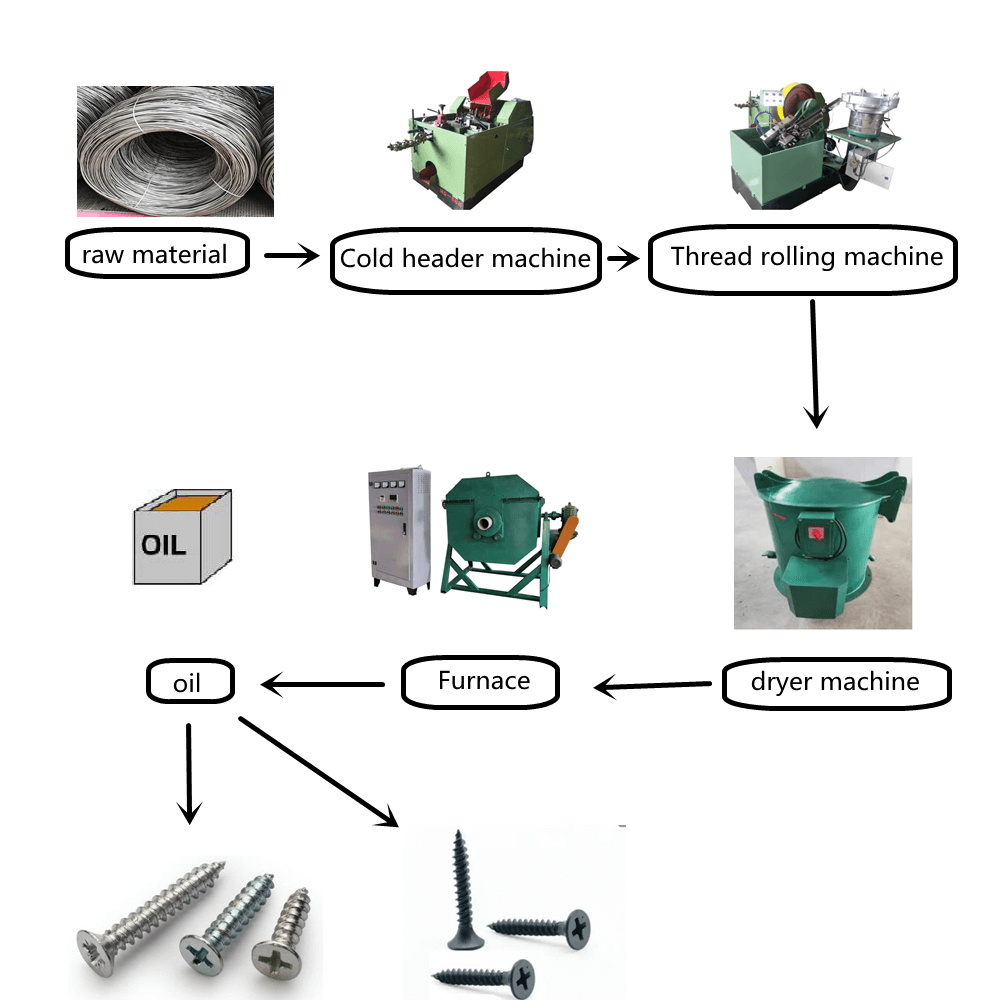

The flow process of Thread rolling screw making machine

Coarse line→ Wire →Heading →Thread rolling → Heat treatment → Plating (color) → Packing

(1). Pull the coarse line to the line patch needed. (Wire drawing machine)

(2). Adjust, produce, and form the head of screw on the heading machine. (Screw heading machine)

(3).Grind tooth on the coil thread rolling machine, and form the screw completely (Thread rolling machine)

(4). Treat the semi-finished screw in the heat treatment according to the standard (Heat treatment furnace)

(5). According to the requirements, process plating etc. (Zinc plating machine)

(6). Packing and out of factor

Machine Features

1. reducing workers' labor intensity

2.safe and reliable

3.easy to operate

4.high processing speed

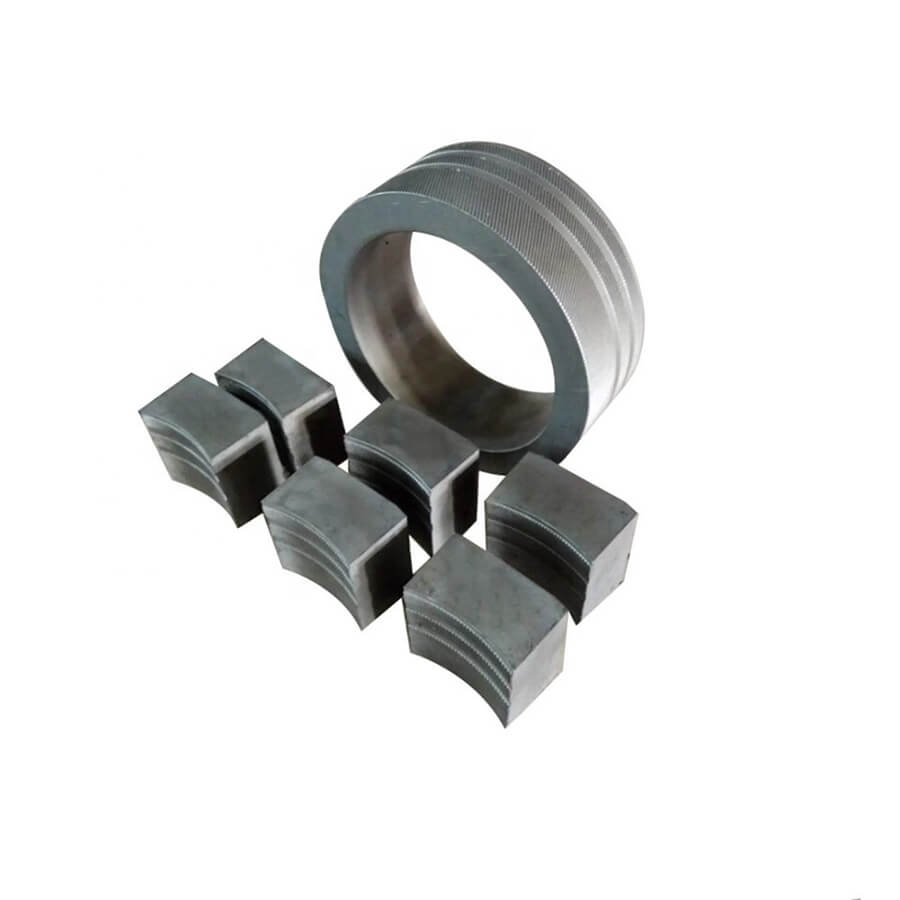

Spare Parts

Package & Loading